-

CALL US:

- (866) 952-3456

Imagine a playground in the 1960s: a 30-foot metal jungle gym, concrete below, no railings, and sharp edges everywhere. It's a chilling thought, isn't it? Like comparing a dusty frontier town to a modern, planned community. Both offer a place to live, but one prioritizes safety and well-being while the other… well, let's just say it was a different time. This drastic difference highlights the vital journey of playground equipment safety standards.

Early playgrounds were often more like obstacle courses designed for daredevils, not safe spaces for children. Towers reaching 30 feet high were common, with little concern for potential falls or other hazards. It's a stark contrast to the playgrounds we know today. For a fascinating glimpse into this evolution, check out the history of playground equipment.

The 1970s marked a turning point. Growing public awareness of the hidden dangers on playgrounds fueled a surge in advocacy for better safety measures. Think of it like a community realizing the need for traffic lights at a busy intersection. Something had to be done.

This period led to the creation of the Consumer Product Safety Commission (CPSC) in 1973. This was a pivotal moment, shifting playground safety from minimal oversight to a more regulated environment. The CPSC's Handbook for Public Playground Safety, published in 1981, provided essential guidelines for playground design, surfacing, and equipment safety. It was like establishing a set of rules for the road, making playgrounds safer for everyone.

If you're curious to learn more about the process of building playgrounds, it offers further insight into the importance of these standards. The evolution of these standards represents a crucial step towards ensuring that playgrounds are true safe havens. Places where children can explore, learn, and grow without unnecessary risks. These advancements paved the way for the comprehensive standards we have today, emphasizing not just the equipment itself, but also its safe design, installation, and maintenance. It's all part of building a better, safer place for kids to play.

For further insights on industry trends and updates, you can explore recent posts on the Hypertype Blog.

Imagine playground safety standards as a symphony. Each organization plays a distinct instrument, and their collaboration creates the beautiful music of safe play. ASTM International, for instance, crafts the technical specifications—think of them as the musical notes on a page. These detailed standards cover everything from materials and dimensions to performance requirements, ensuring the playground is built to a high standard.

Then there's the Consumer Product Safety Commission (CPSC), acting as the conductor. They set the tempo and ensure everyone plays in sync. They provide the regulatory framework, giving ASTM's technical notes legal weight. ASTM defines the "how," while the CPSC often dictates the "must." This collaboration ensures playgrounds can handle the daily wear and tear of energetic children.

There's a crucial difference between voluntary standards and mandatory regulations. Think of it like the difference between a suggested speed limit and a legally enforced one—both aim for safety, but one carries more weight. Voluntary standards, like those from ASTM, are best practices developed by industry experts. Manufacturers choose to adhere to these standards, demonstrating their commitment to safety.

Mandatory regulations, on the other hand, are legally enforceable rules set by government agencies like the CPSC. Understanding this distinction is key when you're selecting playground equipment or evaluating compliance.

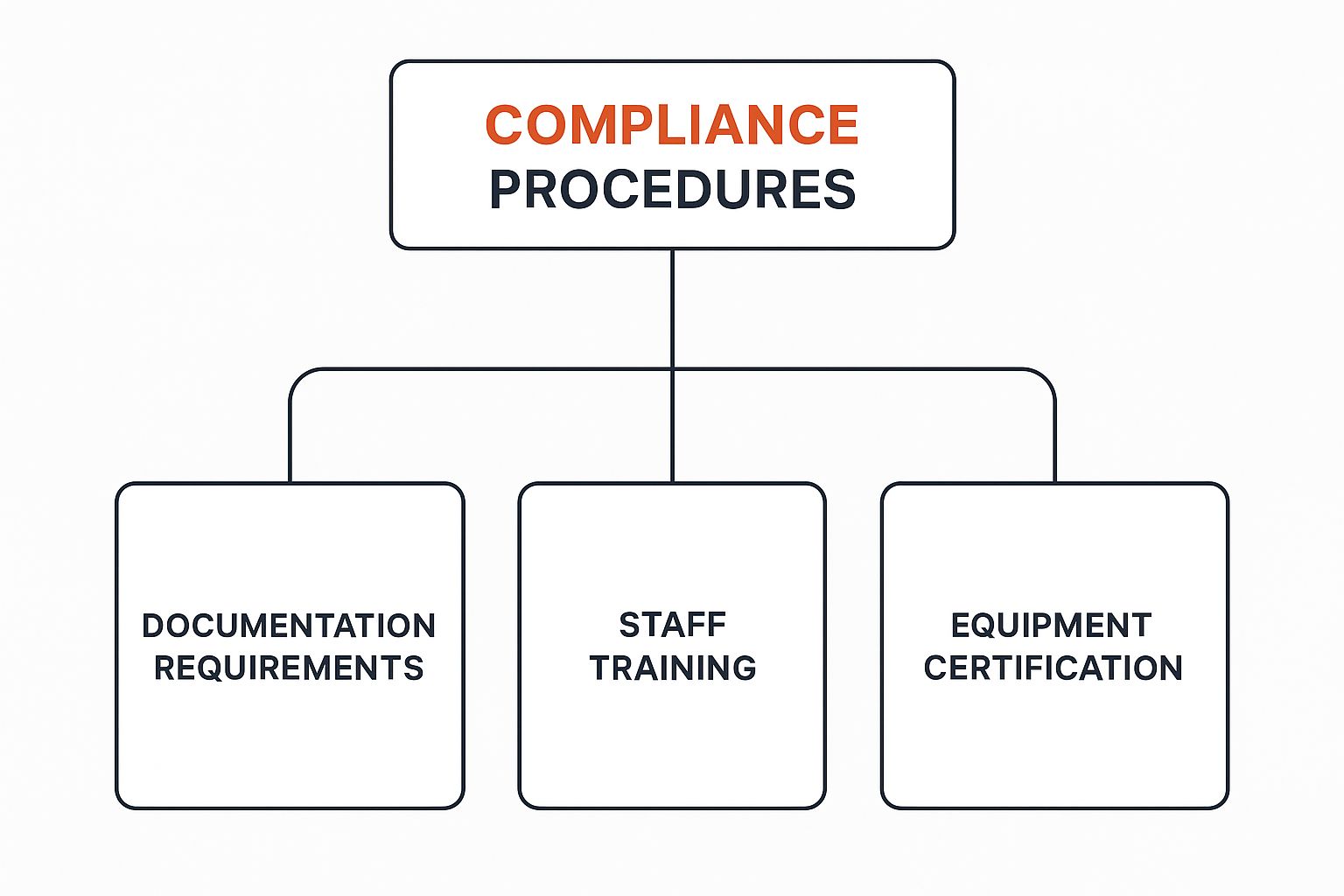

The infographic above illustrates the hierarchy of safety compliance procedures. It shows how documentation, staff training, and equipment certification all contribute to a safe environment. These procedures are interconnected, like gears in a clock. Each plays a vital role, and one weak link can compromise the whole system. This emphasizes the importance of meticulous attention to detail in every area.

Now, let's broaden our view to the international stage. Organizations like the International Organization for Standardization (ISO) strive to harmonize safety requirements across borders. This means a playground built to ISO standards in Europe would offer a similar level of safety to one built to ASTM standards in the US.

This global collaboration is like establishing a universal language of safety, ensuring children can play safely wherever they are. It also simplifies things for manufacturers, making it easier to design and sell equipment internationally and raising the bar for playground safety worldwide. These standards impact everything from the tiny bolts holding the equipment together to the spacing between play structures, demonstrating their comprehensive nature.

To help clarify the roles of these key players, let's look at a comparison table:

Major Playground Safety Organizations and Their Standards

| Organization | Primary Standards | Geographic Scope | Enforcement Type | Key Focus Areas |

|---|---|---|---|---|

| ASTM International | ASTM F1487 (playground equipment), ASTM F1292 (impact attenuation) | International | Voluntary consensus standards | Materials, dimensions, performance requirements, testing methods |

| CPSC | 16 CFR 121 (Safety Standard for Playground Equipment) | United States | Mandatory regulations | Injury prevention, hazard identification, product recalls |

| ISO | ISO 23599 (Playground equipment – Part 1: General safety requirements and test methods) | International | Voluntary consensus standards | Safety management, risk assessment, design guidelines |

| EN (European Committee for Standardization) | EN 1176 (Playground equipment and surfacing) | Europe | Varies by country (can be adopted as national standards) | Safety requirements for public playgrounds, impact attenuation |

This table provides a quick overview of the major organizations and their respective standards, geographic influence, and enforcement approaches. Notice how ASTM and ISO develop voluntary standards, while CPSC creates mandatory regulations within the United States. The EN standards, while developed for Europe, can be adopted by individual countries as national standards, leading to varied enforcement. Understanding these nuances is essential for ensuring playground safety compliance.

Today's playground safety standards aren't just about preventing falls. They're about making sure every child, regardless of ability, can experience the joy of play. Think of a playground where a child in a wheelchair can zoom down the same slide as their friends, or a child with autism can find a quiet, sensory spot designed just for them.

This represents a huge change in how we design playgrounds. We're now using universal design principles, meaning we create spaces usable by everyone, regardless of physical, sensory, or cognitive differences. This isn't just about adding a ramp as an afterthought; it's about weaving accessibility into the very fabric of the playground.

For example, playground safety standards now address accessible routes, ensuring smooth paths connecting all areas. It's like designing a well-planned city with interconnected streets and sidewalks, making it easy to get from point A to point B. They also cover transfer systems, making it simple for children to move from their wheelchairs onto play structures. This is similar to a well-designed bus with a lift, allowing everyone to board easily.

In addition, we're seeing more sensory play elements like musical instruments and textured surfaces. These cater to children with various sensory needs, but honestly, they add a layer of fun for all kids. Imagine a playground with chimes that sing in the wind or a wall with bumpy surfaces to explore – who wouldn't be intrigued? These elements help create a more vibrant and inclusive environment for everyone. Playground safety has evolved to be more welcoming and accessible, with features like wheelchair ramps and sensory play areas becoming commonplace. This shift enhances safety and promotes social inclusion, offering equal opportunities for all children. For further insights, explore the latest global trends in playground safety.

Interestingly, these inclusive features often improve safety for all children. Think about wider ramps. They're essential for wheelchairs, but they also provide extra space for toddlers learning to walk or kids who might trip easily. Clearly defined play zones, helpful for children with autism who appreciate predictable environments, also prevent collisions between kids engaged in different activities. It's like having separate lanes in a swimming pool – everyone has their space and can play safely.

This highlights a crucial point: designing for accessibility makes playgrounds safer and more enjoyable for everyone. It's a win-win!

Think of playground safety standards as the essential rules of the game, ensuring kids can play freely and safely. These standards dictate everything from the height of a slide to the materials used, all working together to minimize risks. Let's explore these crucial guidelines that make playgrounds fun, not hazardous.

Ever wonder why seemingly arbitrary measurements, like a 9-inch opening versus a 3.5-inch one, make such a difference in playground safety? It's not random at all. These numbers come from years of research on child development and injury patterns.

A 9-inch gap, for example, can trap a child's head, while a smaller opening poses less risk. Similarly, guardrails aren't just there to keep kids from tumbling out. Their height and spacing are precisely calculated to prevent falls while still allowing children the freedom to climb and explore.

Even something as fundamental as structural integrity plays a vital role. These requirements ensure the equipment can withstand the daily wear and tear of energetic children. For more in-depth information, check out this helpful resource on playground safety standards.

Think of playground safety features as pieces of a puzzle, all working together to create a safe and enjoyable environment. Fall zones, the soft surfaces beneath the equipment, act like cushions, reducing the impact of falls.

Proper equipment spacing prevents collisions between children on different structures, like a swing set next to a jungle gym. And age-appropriate design ensures that equipment challenges children without overwhelming them – imagine a toddler trying to navigate a climbing wall designed for a teenager!

Just as kids grow and develop at different rates, safety standards adapt to their changing needs. Swings for toddlers, for example, have different requirements than swings designed for older, bigger children. A toddler swing’s lower height and gentler motion are far safer for a little one than a high-speed swing meant for older kids.

This tailored approach continues across all playground equipment. A slide designed for toddlers has a gentler slope and lower height than a slide for older children. This isn’t arbitrary; it’s based on extensive research into child development and play patterns.

Understanding these variations empowers you to assess any playground’s safety. You can confidently determine if the equipment suits the intended age group and whether the layout encourages safe play.

Before we move on, let’s take a closer look at how these safety requirements translate to different types of playground equipment. The following table provides a helpful breakdown:

Essential Safety Requirements by Equipment Type

Detailed breakdown of key safety measurements and requirements for different categories of playground equipment

| Equipment Category | Max Height | Guardrail Requirements | Fall Zone | Age Group | Special Considerations |

|---|---|---|---|---|---|

| Swings (Toddler) | 4ft | Fully enclosed | 6ft minimum | 2-5 years | Soft seat material |

| Swings (Child) | 8ft | Fully enclosed | 8ft minimum | 5-12 years | Durable chain/rope construction |

| Slides (Toddler) | 4ft | Side rails required | 6ft minimum | 2-5 years | Gentle slope |

| Slides (Child) | 8ft | Side rails required | 8ft minimum | 5-12 years | Steeper slope permitted |

| Climbing Structures (Toddler) | 4ft | Fully enclosed stairs/platforms | 6ft minimum | 2-5 years | Wide, easy-to-grip handholds |

| Climbing Structures (Child) | 8ft | Guardrails on elevated platforms | 8ft minimum | 5-12 years | Varied climbing challenges |

This table summarizes the fundamental safety requirements for common playground equipment. Note the differences in maximum heights, guardrail requirements, and fall zones, all tailored to the specific age group. These standards work together to create a playground where children can develop crucial skills, explore their physical abilities, and make lasting memories – all within a secure and stimulating environment.

Think of a playground. Swings, slides, and jungle gyms likely come to mind first. But what's beneath those exciting structures is just as important: the surfacing. It's the unsung hero, the crucial safety net for every adventurous child.

Imagine dropping an egg on a hard concrete sidewalk. Now picture dropping that same egg onto a plush pillow. Big difference, right? That's impact attenuation at work – the ability of a surface to absorb the energy of a fall. Playground surfaces are designed with this principle in mind, aiming to cushion falls and minimize the risk of injury.

Traditional playground surfaces like sand and wood chips have been around for ages. But they come with their own set of challenges. Sand can compact over time, losing its cushioning effect, and wood chips can decompose, attracting pests and requiring frequent replenishment.

Newer engineered surfaces, like poured-in-place rubber, offer a more modern approach. These surfaces provide consistent impact attenuation, are easier to maintain, and offer better accessibility for children with disabilities. Ensuring a safe playground environment involves quick responses to any incidents. For insights on best practices, check out this resource on incident management best practices.

A playground surface isn't a "set it and forget it" kind of deal. Weather, the amount of use it gets, and how well it's maintained all play a part in its effectiveness. Heavy rain can saturate loose-fill materials like wood chips, diminishing their ability to absorb impact. High-traffic areas can compress sand, requiring regular raking to keep it fluffy and safe.

This highlights the importance of routine maintenance. Regular inspections and upkeep, like adding more loose-fill material or fixing damaged rubber surfaces, are vital for ensuring ongoing safety. The shift toward softer surfacing like sand, wood chips, and rubber mulch has played a significant role in lessening the severity of playground injuries.

Safety is the top priority, but budget is always a consideration. Poured-in-place rubber offers fantastic performance and longevity, but has a higher initial cost. Loose-fill materials like wood chips are cheaper upfront, but require more frequent maintenance, potentially increasing costs over time.

Understanding how playground surfaces are tested and rated for various fall heights helps you make informed choices. You can select a surface that offers suitable protection without breaking the bank. By considering these factors, you can create a playground that's both safe and sustainable. Learn more about the evolution of playground safety standards and design here.

Imagine you're baking a cake. You’ve got top-notch ingredients and a recipe from a celebrity chef. But you wouldn't just toss everything in a bowl and hope for the best, right? Installing a playground is much the same. Even with the highest quality equipment and a thorough understanding of playground equipment safety standards, the installation itself is absolutely critical. This is where those standards come alive, transforming into a genuinely safe play environment.

Think of proper anchoring as the foundation of a house. Without a solid base, the entire structure is at risk. The right anchoring techniques ensure the playground equipment remains firmly in place, preventing dangerous tipping or shifting during those energetic play sessions. This is especially important for swings and other moving equipment that experience a lot of force.

Along with secure anchoring, precise spacing between playground components is key. Picture a child leaping from a swing and accidentally colliding with another child on the nearby climbing frame. Ouch! Proper spacing, as outlined in playground equipment safety standards, helps prevent such accidents. Think of it like safe zones on a highway, ensuring enough room between cars to avoid collisions.

Effective drainage is another crucial factor, often overlooked. Puddles create slippery surfaces, increasing the risk of falls. Plus, standing water can damage the playground surface over time, impacting its ability to absorb shock. Planning for proper drainage is essential to maintaining a safe and dry play area.

And let's not forget accessibility. Every child deserves the chance to play. Ramps, transfer systems, and sensory play areas should be seamlessly integrated into the playground design, not tacked on as an afterthought. This isn't just about checking boxes for compliance; it's about creating a welcoming and inclusive environment where every child feels they belong. For more practical advice on outdoor playset installations, check out this guide.

Certified installers follow a meticulous inspection process, verifying that every single aspect of the playground meets safety standards. They check things like bolt torque specifications – making sure they're tight enough to hold but not so tight that they strip – and confirm that all hardware meets the required standards.

These seemingly small details can have a big impact. Think of it like a pilot's control panel – even a minor malfunction can have serious consequences. This thorough verification process transforms a collection of playground components into a truly safe play area.

The final piece of the puzzle is proper documentation. This involves recording the installation process, verifying that all equipment meets playground equipment safety standards, and outlining maintenance schedules. This documentation not only protects your organization but also helps you track the lifespan of your equipment and plan for future upgrades or repairs. It's like a passport for your playground, proving its compliance and providing a record of its history. By ensuring proper installation, ongoing maintenance, and detailed documentation, you create a playground that remains a source of joy and safe exploration for years to come.

A brand new playground, sparkling with freshly installed equipment, isn't a "set it and forget it" deal. Think of it like a new car – it needs regular maintenance to keep it running smoothly and safely. Just like you wouldn't skip oil changes and tire rotations, you can't ignore the upkeep required for a safe and enjoyable playground.

Playground maintenance involves a multi-layered approach, much like caring for your health. Daily visual inspections are like brushing your teeth – quick and easy, but crucial for catching small issues before they become big problems. A staff member can simply scan for obvious hazards like broken equipment, loose bolts, or debris.

Monthly checks are a bit more involved, like a regular check-up with your doctor. These might include tightening bolts, lubricating moving parts, and checking the depth of loose-fill surfacing materials like wood chips. This helps ensure everything is in good working order.

Finally, annual audits are like a comprehensive physical. A certified playground safety inspector, much like a specialist, conducts a thorough assessment using their expertise and specialized tools to identify any hidden dangers. This in-depth analysis is essential for preventing long-term issues.

Learning to spot potential hazards is like learning to read the subtle signs of a changing weather pattern. A worn swing seat might seem minor, but it’s a sign of potential future failure. A loose bolt, though small, could compromise the entire structure's integrity. Small cracks in a poured-in-place rubber surface are like tiny fissures in a dam – they can quickly expand and create major problems.

Keeping records of all inspections and maintenance is crucial. Think of these records like your playground's medical history. They document its care and condition, demonstrating your commitment to safety and providing evidence of due diligence in case of an incident. These records are your best defense against potential liability.

Time, weather, and usage all take their toll, just like they do on your house. Sun exposure can weaken plastic components, heavy rain can affect loose-fill surfacing, and high traffic can compact sand. As children grow and their play styles change, the equipment is subjected to different stresses and strains.

Regular upkeep, like replenishing loose-fill material, repairing damaged surfaces, or replacing worn parts, is crucial. ASTM International provides standards like ASTM F1487 for equipment safety. Learn more about global trends in playground safety compliance. Countries worldwide are aligning their standards for consistent protection and international collaboration.

A proactive approach to maintenance ensures your playground remains safe and vibrant for years to come. This not only protects children but also safeguards your organization and reduces long-term costs. It keeps your playground a thriving hub of fun and activity.

Ready to create a safer playground? Contact Assembly Smart for professional installation and maintenance services that prioritize safety, quality, and your peace of mind. We specialize in assembling and maintaining playground equipment, ensuring it adheres to all relevant safety standards.